Micro-laser uses

Laser Processes

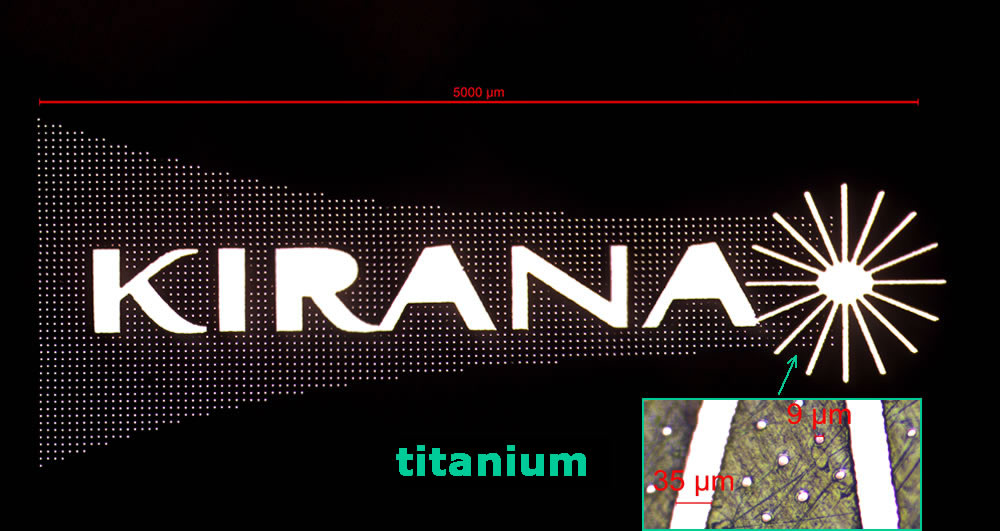

- Micro-drilling

- Precision micro-cutting

- Surface micro-structuring

- Ablation of thin film

- Micro-engraving

- Micro-milling

- Scribing

- Dicing

- Laser Marking

Technical Specifications

- Hole size: down to 1 μm (0.001 mm)

- Cutting/engraving width: down to 5 μm (0.005 mm)

- Accuracy and repeatability: down to 1 μm (0.001 mm)

- Aspect-ratio (thickness/lateral dimension): up to 50:1

- Thickness: up to 2 mm

Materials

- Metals, alloys and superalloys (steel, tungsten, brass, copper, aluminium, gold, silver, inconel, hastelloy, haynes, nickel, titanium, nitinol, molybdenum, tantalum, others)

- Polymers (kapton, teflon, PC, PET, PVC, PMMA, PES; PEEK, FR4, others)

- Ceramics (alumina, silicon carbide, silicon nitride, lithium niobate, zirconia, others)

- Dielectrics (glass, pyrex, fused silica, quartz, sapphire, others)

- Semiconductors (silicon, germanium, gallium arsenide, gallium nitride, others)

- Carbon Composites

Applications

- Micro-fluidics

- Precision micro-holes for micro-filters, micro-valves, nebulizers, injectors, nozzles, other

- Micro-channels for micro-fluidic devices

- Precision micro-holes for leak detection testing and flow control

- Calibrated orifices for validation of inspection machines for vials, cartridges, syringes, carpoules and ampoules.

- Micro-electronics and Photonics

- Micro-machining of substrates such as silicon, glass, polymers, ceramics and composites

- Micro-channels in polymers, glass and silicon (MEMS technology)

- Selective removal of thin film

- Calibrated orifices and slits for optical apertures

- Micro-holes and micro-cuts for flexible circuits manufacture

- Micro-mechanics

- Micro-structures for high specifications components

- Micro-texturing for tribological surfaces (i.e. engine components)

- Micro-milling for micro-molds

Sectors

- Automotive

- Aerospace

- Precision engineering

- Energy

- Medical

- Biotechnology

- Other