Micromachining

Laser micromachining process

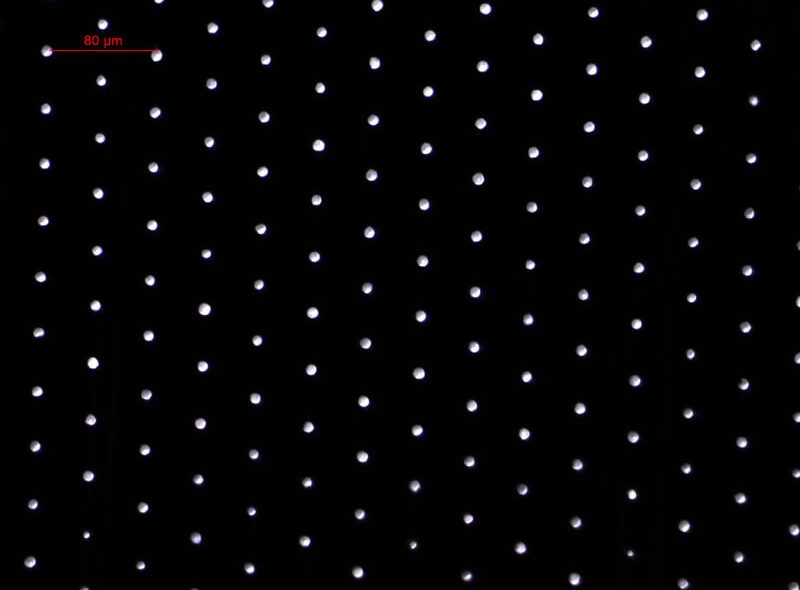

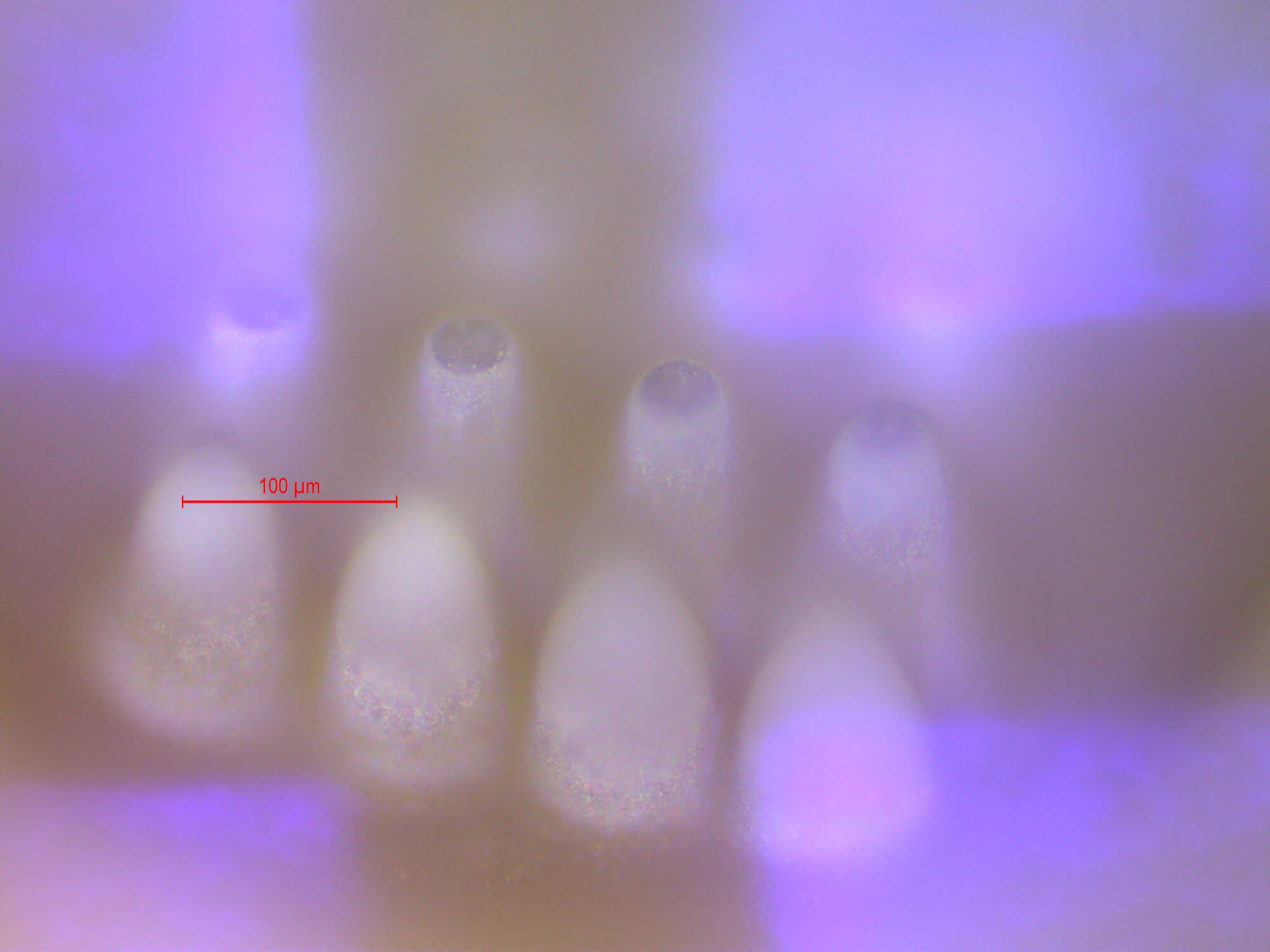

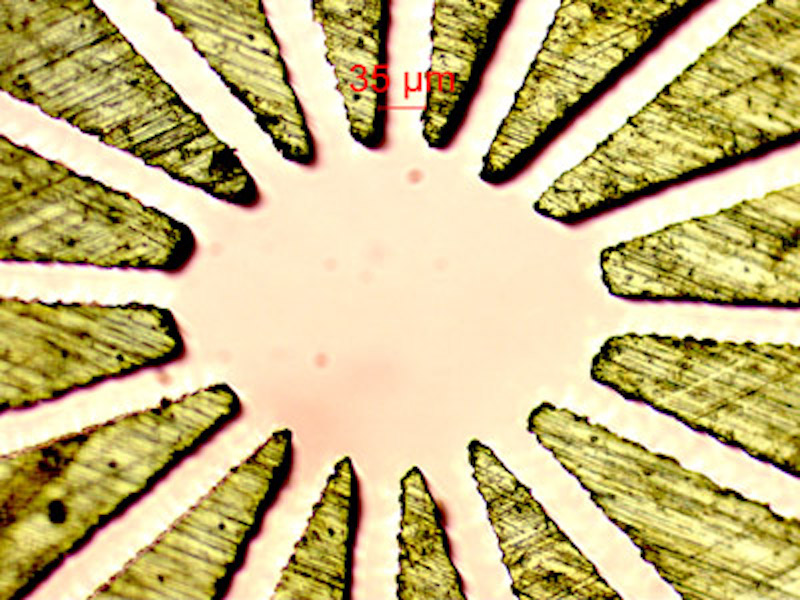

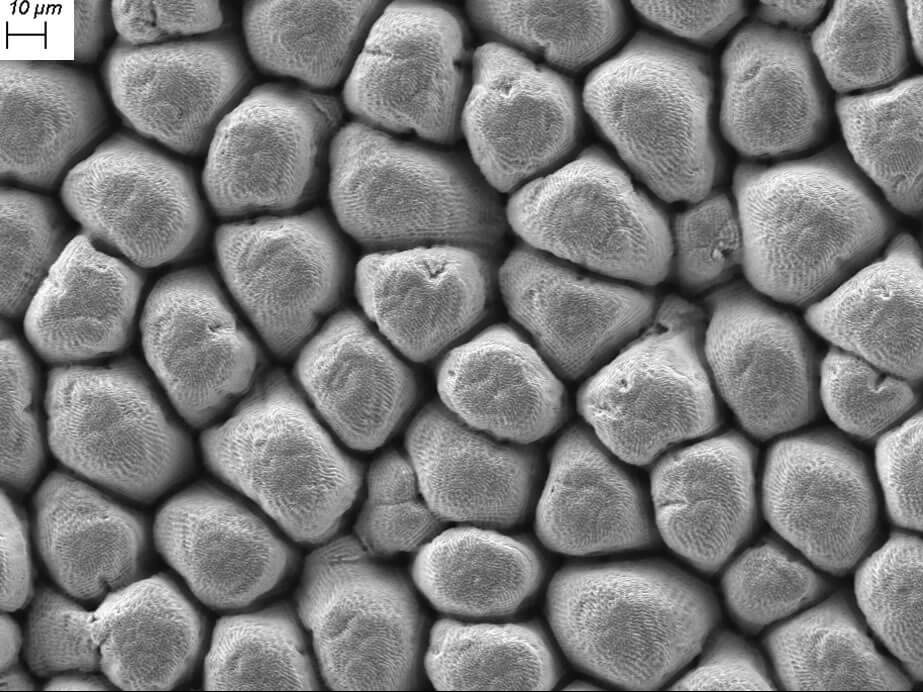

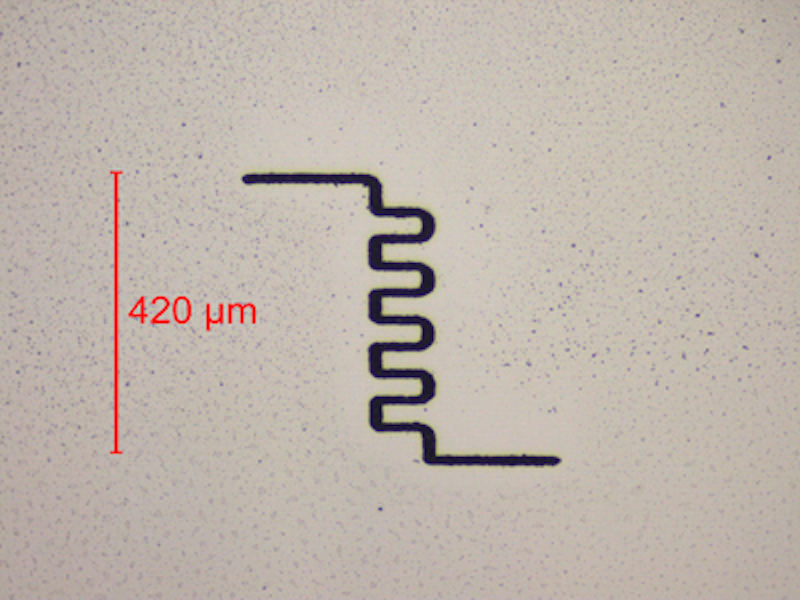

Our expertise includes processes such as drilling micro-holes, precision cutting small parts, surface micro-structuring, ablation of thin film, micro-engraving, micro-milling and special laser marking, in a wide range of materials: metals, ceramics, polymers, dielectrics (glass and other), semiconductors (silicon and others), composites. Kirana deals exclusively with laser processing and therefore never provides a "finished" product, but delivers to customers parts to be integrated into more complex systems.

Technical Specifications

- Hole size: down to 1 μm (0.001 mm)

- Cutting/engraving width: down to 5 μm (0.005 mm)

- Accuracy and repeatability: down to 1 μm (0.001 mm)

- Aspect-ratio (thickness/lateral dimension): up to 50:1

- Thickness: up to 2 mm